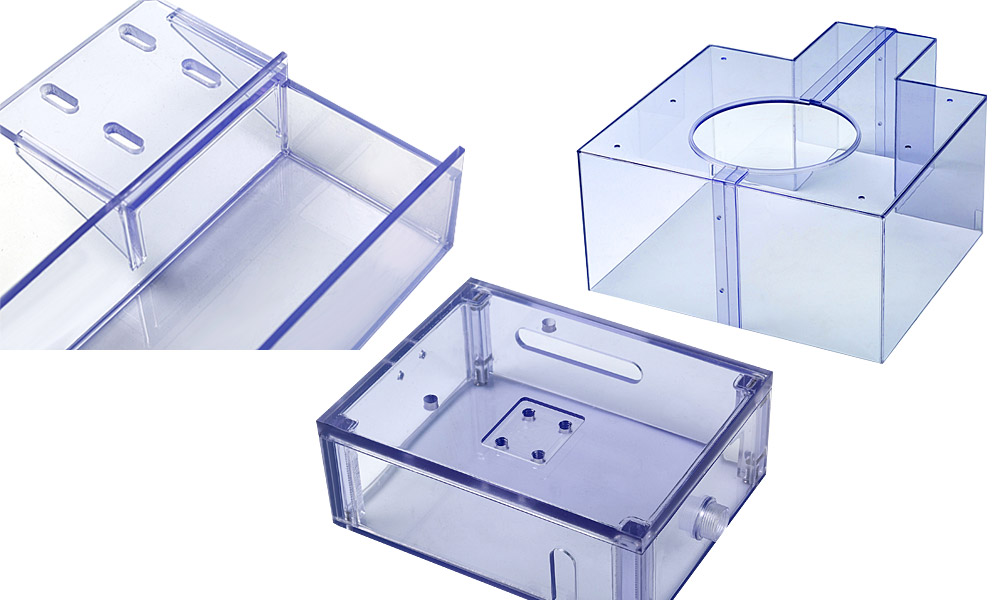

Novaplas Precision has many years of experience in the gluing of plastics for professional use. It is a common post-processing technique for plastics. The gluing of plastic requires specific professional expertise, accuracy and the right materials.

Gluing techniques differ depending on the type of plastic and glue. Specialist knowledge is required to make the best choice for a long-term adhesive bond.

There are many ways to glue plastics. This is due to different techniques and the different types of glue. We always look for the best possible combination of technique and glue to get the best results. So when gluing plastics, we take into account such things as porosity, absorbency and other material properties of both glue and the type of plastic.

Here are some types of plastic which have properties suitable for gluing:

• PVC (Polyvinyl chloride)

• PMMA (Polymethyl Methacrylate)

• PC (Polycarbonate)

• ABS (Acrylonitrile Butadiene Styrene)

The production of cutting-edge electronic microdevices requires stringent quality control, and any variation in the manufacturing process can have a significant impact on product performance. To meet the ever-increasing demand for high-quality products, manufacturers must stay ahead of the curve by implementing advanced process control measures.

Our ISO 9001:2015-certified company operates out of a 30,000-square-foot facility with an open manufacturing area of 21,000 square feet, where we manufacture a versatile array of wet process equipment solutions for semiconductor production and related applications. In addition, our product capabilities extend to clean room essentials, fume hoods, custom tanks, and lab furniture, with services including machining, fabrication, welding, and material distribution.

Machining plastic is just one of our specialties in plastic machining. We have solutions for all aspects of plastic machining. If you have any questions about CNC machining at Novaplas Precision, please don't hesitate to contact us. The contact details can be found below.