The production of an IC chip requires highly specialized equipment that operates under a variety of challenging environments such as:

The production of an IC chip requires highly specialized equipment that operates under a variety of challenging environments such as:

Plasma under vacuum

Elevated temperature

Contact with highly abrasive solutiuons

Exposure to a variety of very aggressive chemicals

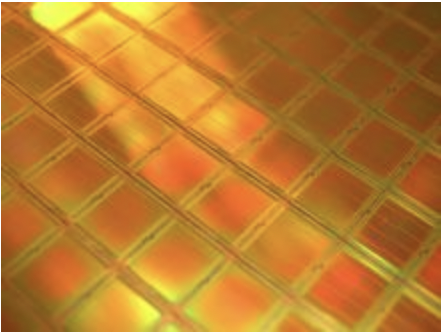

Mitsubishi Chemical Advanced Materials Engineering Plastic Products has developed materials that meet the strictest requirements for low contamination consistent wafer manuafacturing, yet with a focus on delivering low-cost solutions vs traditional materials such as quartz and ceramics. Mitsubishi Chemical Advanced Materials materials are designed to be used throughout the wafer production process.

Copy exact materials available anywhere on the globe.

Extensive material selection, engineering support and testing capabilities.

Machining capability to support quick turn NPI application development.

The most extensive portfolio of materials specifically designed for use in Wet Process Tools.

The global leader in manufacturing the materials used for CMP ring applications including Techtron® PPS, the global standard for CMP applications.

Materials designed to deliver cost and performance for Dry Process Tools such as Etch, CVD and Ion Implant.

Products | Applications |

|

|