Welding is often associated with metal, but did you know that plastic is also suitable for welding? Plastic welding is a specialised process in plastic processing that makes it possible to join thermoplastics together.

Perfect results require extensive knowledge and expertise of both welding techniques and weld seam constructions. Novaplas Precision can do this to the highest degree of precision and craftsmanship.

Semiconductor manufacturing and the overall technology industry demands precision, reliability, and consistency.

The production of cutting-edge electronic microdevices requires stringent quality control, and any variation in the manufacturing process can have a significant impact on product performance. To meet the ever-increasing demand for high-quality products, manufacturers must stay ahead of the curve by implementing advanced process control measures.

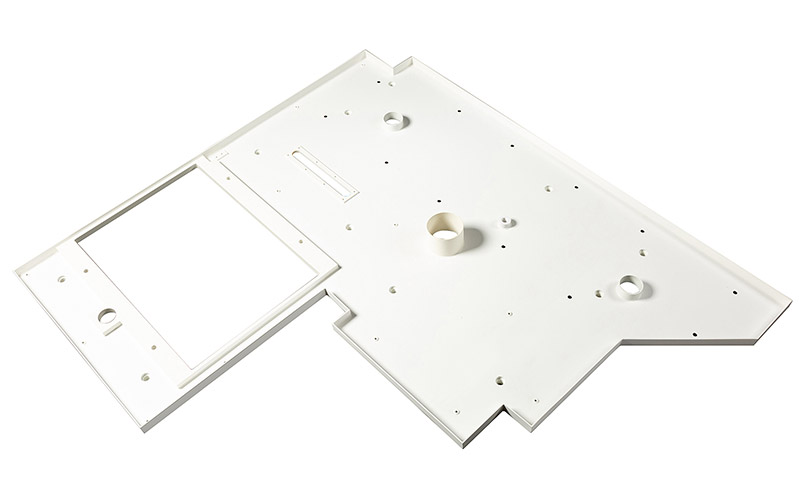

Our ISO 9001:2015-certified company operates out of a 30,000-square-foot facility with an open manufacturing area of 21,000 square feet, where we manufacture a versatile array of wet process equipment solutions for semiconductor production and related applications. In addition, our product capabilities extend to clean room essentials, fume hoods, custom tanks, and lab furniture, with services including machining, fabrication, welding, and material distribution.

In addition, Novaplas Precision does hot gas welding, also known as wire welding. This technique bonds similar thermoplastics together using air at high temperatures.

For wire welding, we use a specially designed handheld hot air dryer. Plastic and welding wire are heated simultaneously and evenly with hot air so that the parts fuse together. When the product has cooled, the end result is a solid bond.

Wet processing equipment is compatible with multiple types of materials, such as:

FM-approved chlorinated polyvinyl chloride (PVC-C).PVC-C combines chemical resistance and durability for various wet processing applications.

Polyethylene (PE). Whether it’s high-density polyethylene (HDPE), low-density polyethylene (LDPE), or ultra-high molecular weight polyethylene (UHMWPE), versatile PE plastic is an ideal material for applications requiring chemical and impact resistance or FDA approval.

Polypropylene (PP).This low-density and -friction crystalline thermoplastic is another versatile and durable choice that resists high temperatures. It’s useful in many applications for being tough yet flexible.

Polytetrafluoroethylene (PTFE).PTFE is useful for wet processing applications because of its nonreactivity and resistance to chemicals and water. Often referred to by the brand name Teflon®, this dense synthetic fluoropolymer is also known for its high thermal stability and versatility.

Polyvinylidene fluoride (PVDF).PVDF is another nonreactive fluoropolymer that’s beneficial for its resistance to harsh chemicals and its high thermal stability. It’s ideal for high-purity applications and has a lower density than many other fluoropolymers.

Polyvinyl chloride (PVC).This synthetic thermoplastic is lightweight yet durable, holding up well against chemicals and corrosion for long-term use. Highly versatile, it also offers excellent performance for its price.

However, this technique requires specific expertise because each type of plastic has a different melting point. If the plastic is heated to above its ideal temperature, it can be permanently damaged. In short, this welding method must be carried out with extreme accuracy.

The thermoplastics we can weld are:

• PP (Polypropylene)

• HDPE (High Density Polyethylene)

• PVC

• PVDF

• PC

Machining plastic is just one of our specialties in plastic machining. We have solutions for all aspects of plastic machining. If you have any questions about CNC machining at Novaplas Precision, please don't hesitate to contact us. The contact details can be found below.